About Steelsworth

The company has been the market leader since more than 71 years. The factory is fully equipped with its own machine shop, assembly line, etc. with expertise in commissioning of tea factories.

Our Company History

From 1950 to 1954 the workshop was developed to manufacture Oil and Water tanks, Trailers, Structures, Tea Machineries etc. A foundry was also setup for casting work. Repairs of Tea machinery and manufacture of their Spares were also undertaken.

From 1954 onwards, more plant and equipment were added and new products were introduced periodically and Today, Steelsworth is the most prominent manufacturer and exporter of Tea processing machinery in the world.

Capability

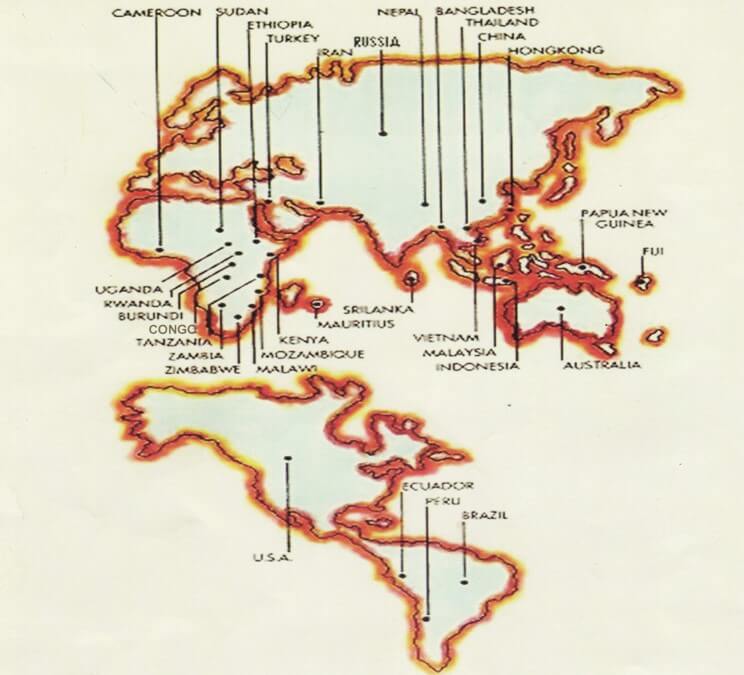

Steelsworth is a pioneer in the manufacturing of Tea processing machineries. We have a large base of satisfied clients in the Indian domestic market as well as across the entire tea producing world spread over 35 countries.

We are a regular supplier of Tea Processing Machinery to the overseas market for more than 50 years. We also undertake complete tea factory projects on turn-key basis from conception to commissioning. Various such projects have been executed by us in Nepal, Unilever Pakistan, Iran, China, Indonesia, Tanzania, Bangladesh, Turkey, Sri Lanka, Kenya etc.

Steelsworth has a most modern factory for production of Tea Machinery at Tinsukia, Assam, the heart of the Tea industry in India, and a large force of technically qualified and dedicated engineers and workmen. Our modern plant is equipped with quality assurance laboratory and quality control department to maintain consistently high quality standard products. The Steelsworth workshop is the largest integrated manufacturing facility of its kind. The factory is equipped with a machine-shop having computerized numerically controlled machines, and a streamlined assembly line. We are capable of providing services to our clients worldwide either directly or through the networking of agents strategically located in the various tea areas.

Exports

TEA PROCESSING & RESEARCH CENTRE

A research and development centre was established in 1967, which has enabled better technology, improvements in existing products, cost savings, introduction of a new range of modern and sophisticated tea machinery.

Until a few years ago, Tea production was based entirely on batch production. Our governments recognized R&D; cell has revolutionized this by making most steps continuous. It is hoped that the entire process will soon become continuous. The world famous CTC machine is of cups of tea beverage for any given weight of Tea as compared to the Non-CTC Orthodox Tea.